N series

Products Charactristics

Bedless Structure

- Space saving with Bedless

- High accuracy with Bedless

- High rigidity with Bedless

Space saving with Bedless

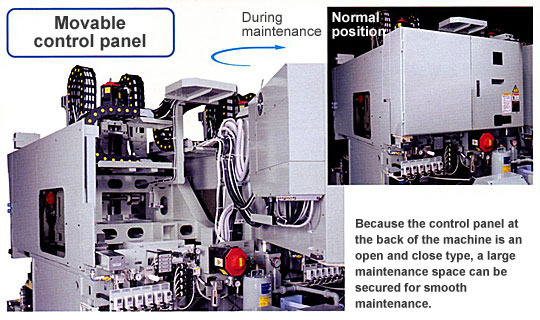

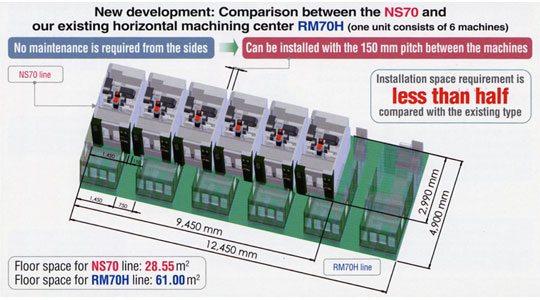

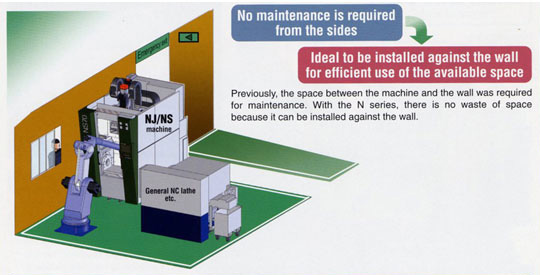

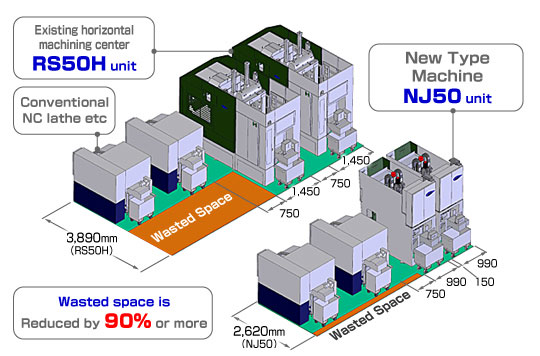

Locating maintenance equipments at front and rear sides of the machine, it can save the maintenance from both sides, can install machine with few space between machines and set it along the wall as machine lay-out.

Reduction of the wasted space for shaft machining when our existing horizontal machining center RS50H is switched to the NJ50.

High accuracy with Bedless

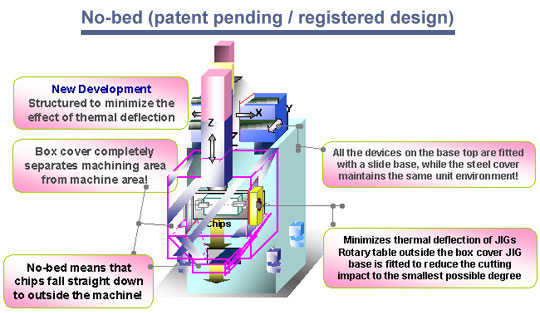

Below the workpiece, there is no component because of bedless structure. With this structure, it enable the drops of machining chip or cutting liquid (coolant) not to touch the machine. Therefore, there is few heat effect by chips or coolant to the machine, and machining accuracy can be kept in good condition for a long continuous operation.

High rigidity with Bedless

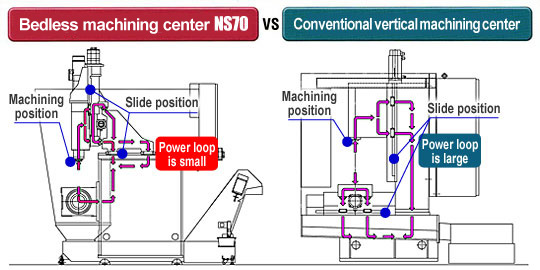

Fixures and spindle sliding unit is fixed on the same body. This shortens the distance from machining point (top edge of the tool) and workpiece on fixture, and minimize the power loop for achieving high rigidity performance.